Before reading, some quick notes

This project may seem dumb and futile. However, I am very happy that I learned many things along the way (woodworking and such), and I believe that this technology (particularly the conveyor system) can have other uses: notably trash collection or some sort of disposal system.

This project took place during the Fall 2023 semester.

Update (Jan 26 2024): I am now a teaching assistant (TA) for the class, and this project has been referenced multiple times by the professor as what students should not do.

How this project came about

Georgia Tech has the Create-X entrepreneurship program, which is an accelerator for startups that is held over the summer (also in Spring starting 2024!). You get all the help you need there and some funding as well.

Create-X capstone is an interdisciplinary class at Georgia Tech that counts for Junior/Senior design (I don’t understand the difference) and only takes 1 semester (most senior design courses take 2-3 semesters). The class is made up of Computer Science (CS), Mechanical engineers (ME), Electrical and Computer Engineers (ECE), Industrial and Systems Engineers (ISYE) and Biomedical Engineering (BME) majors (others too but too little to count), and the goal is to “start a company” over the course of a semester. A neat perk of taking this class is that you get to choose your team (4-6 people), what you work on, and every team gets automatic admission to Spring/Summer Create-X accelerator program.

You assemble your team in week 1, and the first month is spent doing 100+ customer interviews. This means do not interview students, but instead adults outside of your social circle. This is the hardest thing for many engineers in the class. (Obviously you can interview students if your product will be directed to them, but it is not recommended). There are not any rules, but we were advised to not attempt any of the following:

- Dating app

- Social network

- Friend making app

With this in mind, I (a CS major) joined 4 other classmates (didn’t know them): 3 MEs and one ECE. We can basically do anything.

Customer Interviews

The mentors start off by saying “many of you probably came in with ideas, but we want problems instead”. They rather have the “idea” people attend the idea-to-prototype class instead (I2P), as they don’t conduct customer interviews.

Despite this, my team was composed of disc golfers, so they wished to explore that field (pun intended).

For the first month we asked around 100 people, went to many disc golf places, and didn’t find anything concrete. Even our interviews outside of the disc golf scene didn’t yield anything tangible. It sucked. We came up with 2 possibilities a couple days before our first report and presentation deadline:

- Disc Golf tracker (a slap on gyro/accelerometer) to get statistics & metrics on your throws

- A disc golf picker upper

Naturally, I was the deciding vote, and opted for the second. (Guys come on, 3 MEs on a tiny piece of hardware that will basically only be electrical engineering, embedded systems, and kinematic equations? Big thing sounded more fun) <- this is obviously not exactly the reason for the choice but I’ll keep the mystery ;).

Our Pitch/Business Thesis

Disc golf companies will buy a disc retrieval system for utility vehicles because of the increased profits and scalability impacts on their practice clinics.

The disc golf clinic equivalent in regular “ball” golf is a driving range. Except, clinics are competition dependent and therefore change location all the time. It is used as a way for disc golf manufacturers to market their products by having people throw.

The “problem” is that there is no way to pick up the discs automatically, so the whole session must stop, everyone walks ~100 yards, comes back, and then can start again. No, you can’t have an individual picking up the discs as they are not frisbees, they are smaller (hard to see and catch) and hurt when striking someone.

Now, you may be thinking: “wow this is the dumbest idea I have heard of”, and I wouldn’t blame you (I thought so too, although I almost convinced myself a few times it was kind of good). I will say in post, that Sam Altman did say in 2014 that you want to think about how the market is going to evolve/grow, which is terrific for disc golf ideas. You can see for yourself with the UDisc annual growth reports, where many countries have double-digit growth numbers for number of courses (🇳🇴 Norway: ▲ 31%, 🇩🇰 Denmark: ▲ 30%, 🇳🇿 New Zealand: ▲ 29%, 🇨🇭 Switzerland: ▲ 26%, 🇫🇷 France: ▲ 24%). So at minimum we had this argument (which we used in our reports and presentations).

Related Products and Initial Thoughts

We decided our product should be designed to be used like a golf ball picker upper, mounted on a UTV. See the image below.

As first, we believed that we could have a roller with many suction cups that would feed the discs into a basket (very similar to the image above), as there are suction cup poles to get a single disc out of trees.

However, our suction cups were bad quality, and when there was a spec of dirt, grip was lost (even with a vacuum sucking air in from the inside of the cup).

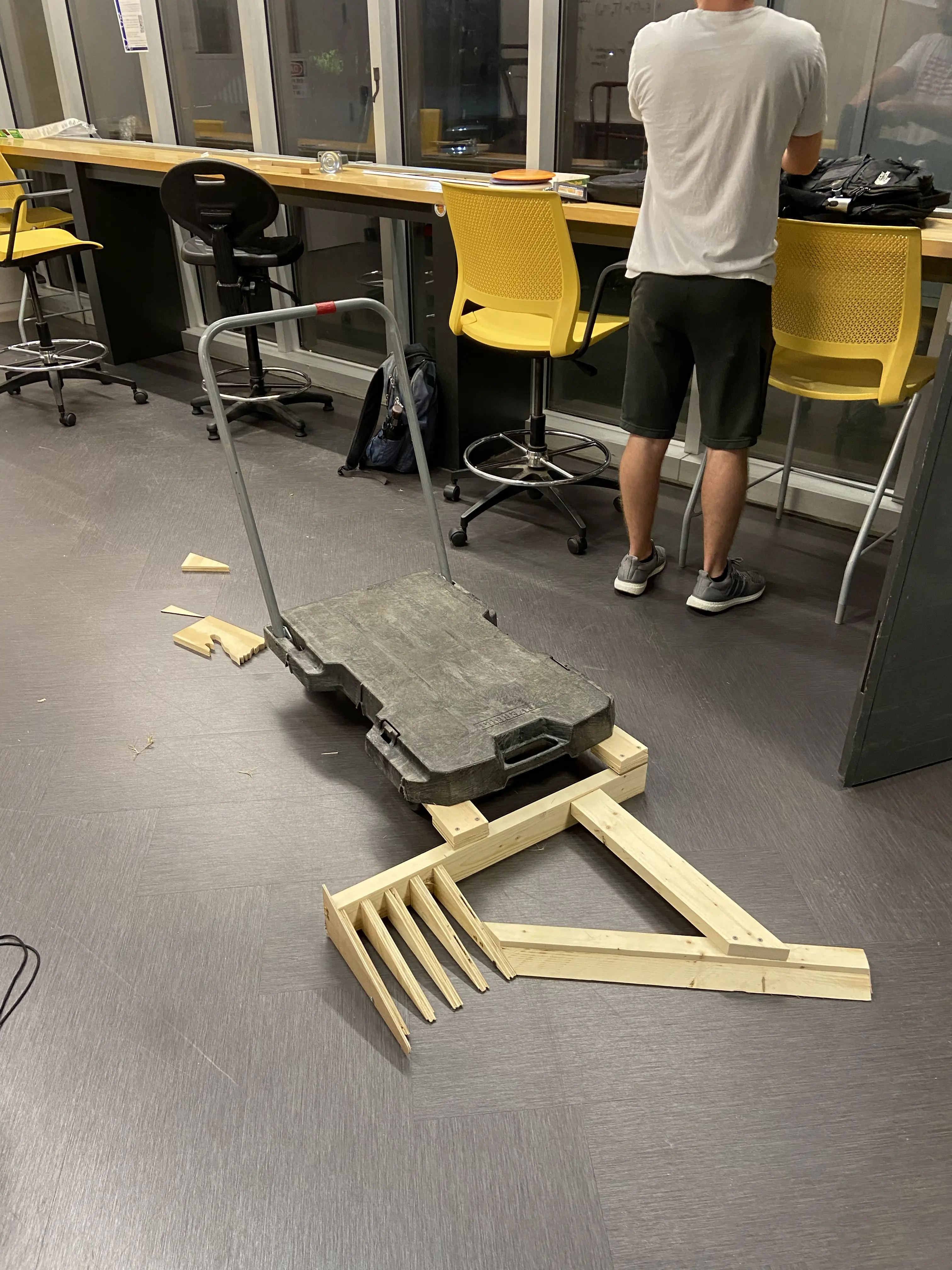

Therefore, we make a rake.

| First rake | Second, less steep rake |

|---|---|

|  |

This bench-level prototyping led to our first prototype (CAD was done AFTER building for the presentation, sorry professor :/).

| — | — |

|---|---|

|  |

Surprisingly, this worked well! We would push it through the grass where discs were laying, and they would naturally be funneled to the rake on the right side (from pushing POV).

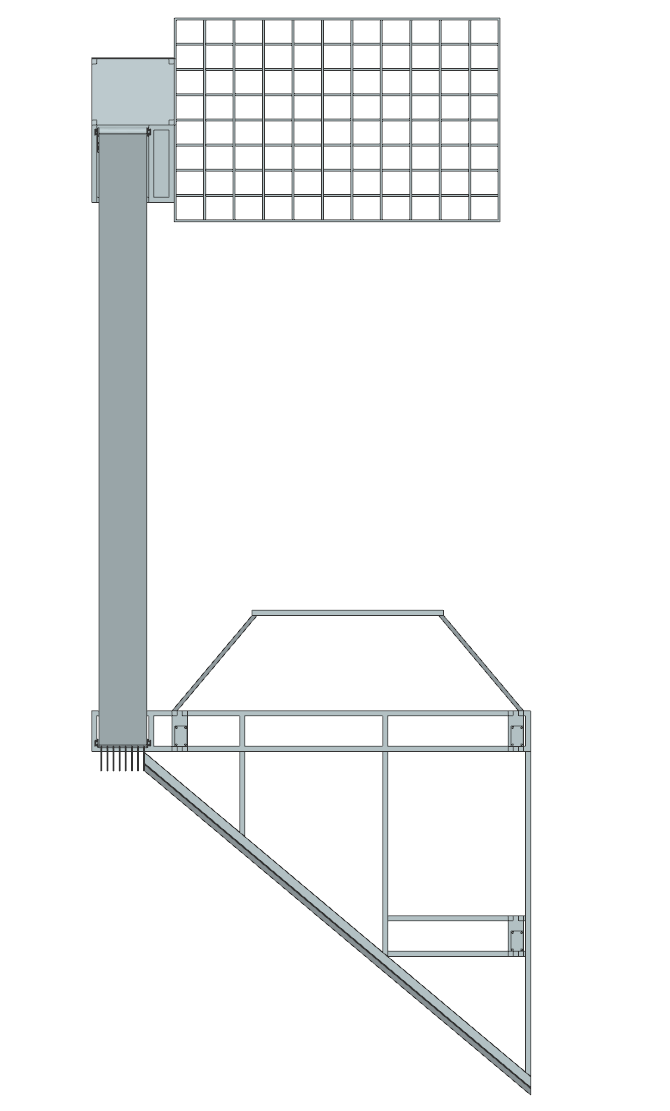

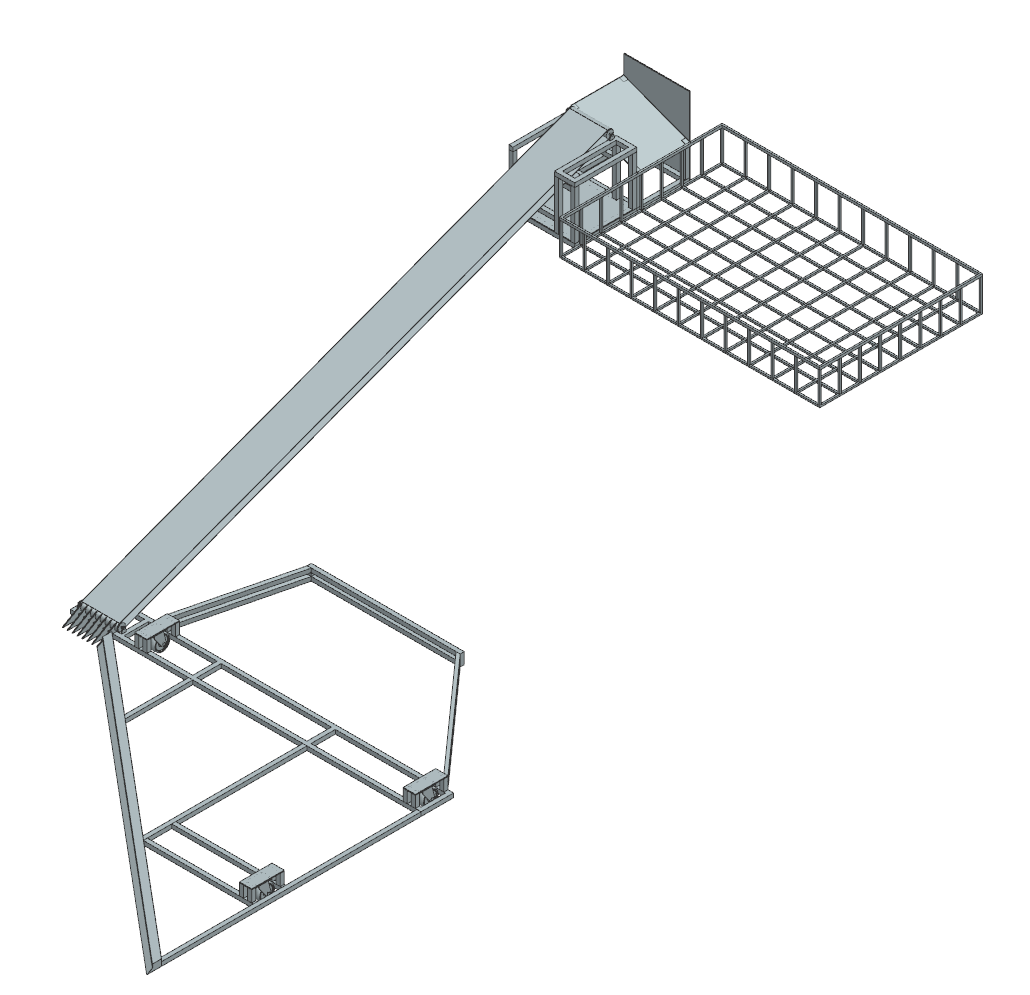

Our plan was to have a conveyor belt right behind the rake to bring the discs to some basket. One unrealistic version of this conceptualized having the conveyor run along the side of the UTV (blocking the door) to dump the discs in the back storage basket. You can see the CAD of that below:

| — | — |

|---|---|

|  |

Final design and prototyping

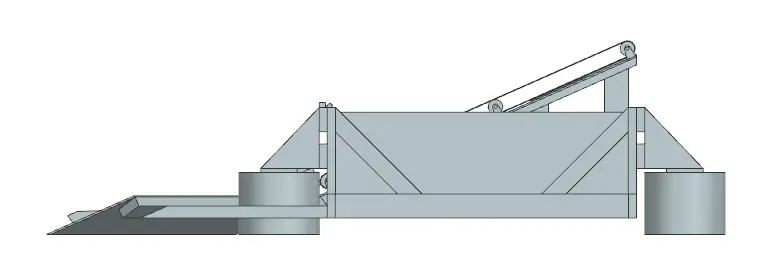

After presentation 2, our team determined that we had to ditch the long conveyor idea, meaning our storage basket must be between the rake and the UTV. This made the single-funnel design over 6ft long, as our storage was designed to hold 300 discs (not neatly stacked!). I suggested making a 2 funnel (what I thought was a regular funnel??) design with the rake in the middle, so that we can have 1 basket on either side of the rake.

Here is the initial (non-cad) version:

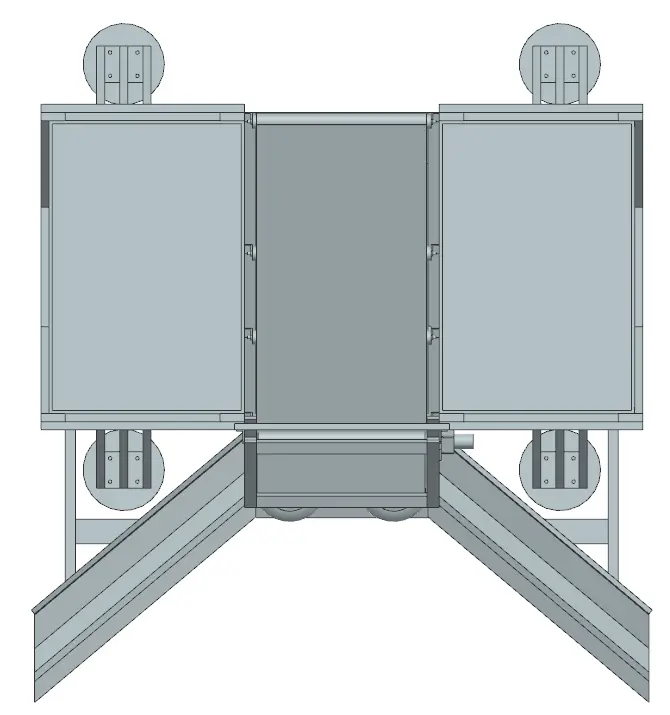

Here is the CAD for the final design (the huge cylinders represent the placement and volume occupied by caster wheels):

| — | — |

|---|---|

|  |

Now, why 2 storage baskets with this design? Why not 1 large one? We need depth to hold 300 discs, so we would have a conveyor (soon 2!) to bring the discs up the rake, up a ramp, to a wedge that would split them into either (now tall) basket. Each basket would hold about 150 discs (unevenly stacked).

However, at this point (and 8th redesign…) we had 2 weeks before the Capstone Expo, the deadline for our project. Although the Expo doesn’t require you to have a working prototype, a few thousand people attend, with judges, cash prizes and an opportunity to attend the InVenture Prize.

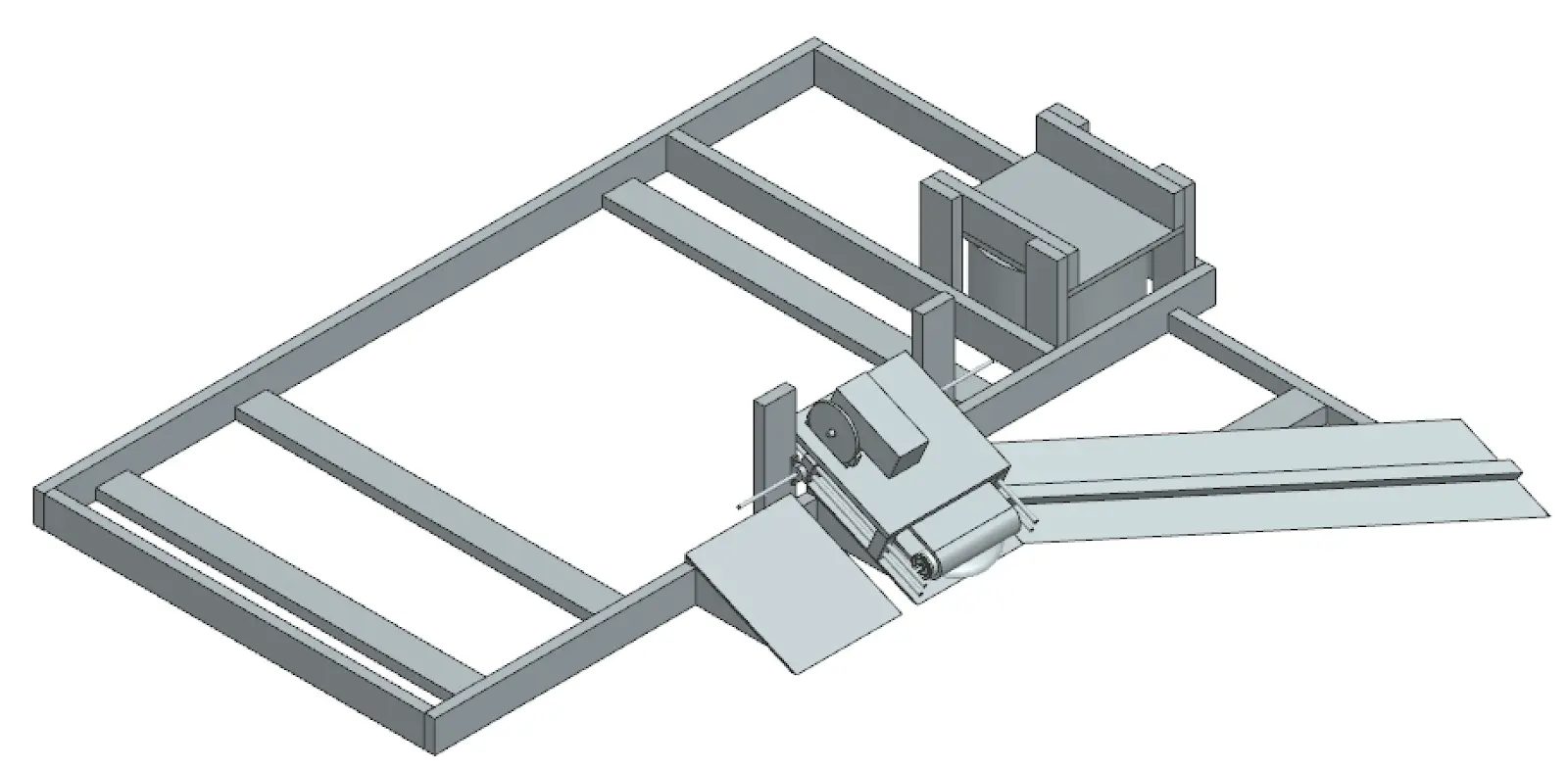

Therefore, we decided to build a “scaled down” version of our final design. This would remove the 2 storage baskets, the UTV mount, and the 2-conveyor belt and ramp. Instead, we would build the full frame, reposition the caster wheels, and make half of the funnel/rake system, with half of the conveyor belt (width).

Here is the CAD of said scaled down design (the small rectangle next to the gear represents a hypothetical motor placement):

The conveyor

This part was our biggest challenge, as we had to make a top conveyor. Our testing (using my grippy bicycle tires) showed that a bottom-side conveyor wouldn’t be able to grip discs that are right side up. The image below shows the upper and under side of a disc, and the underside has a small lip that is easy to grip, but the top is smooth.

Another obstacle was calculating the friction coefficient needed for our belt, as the coefficient of friction of the disc plastic is proprietary.

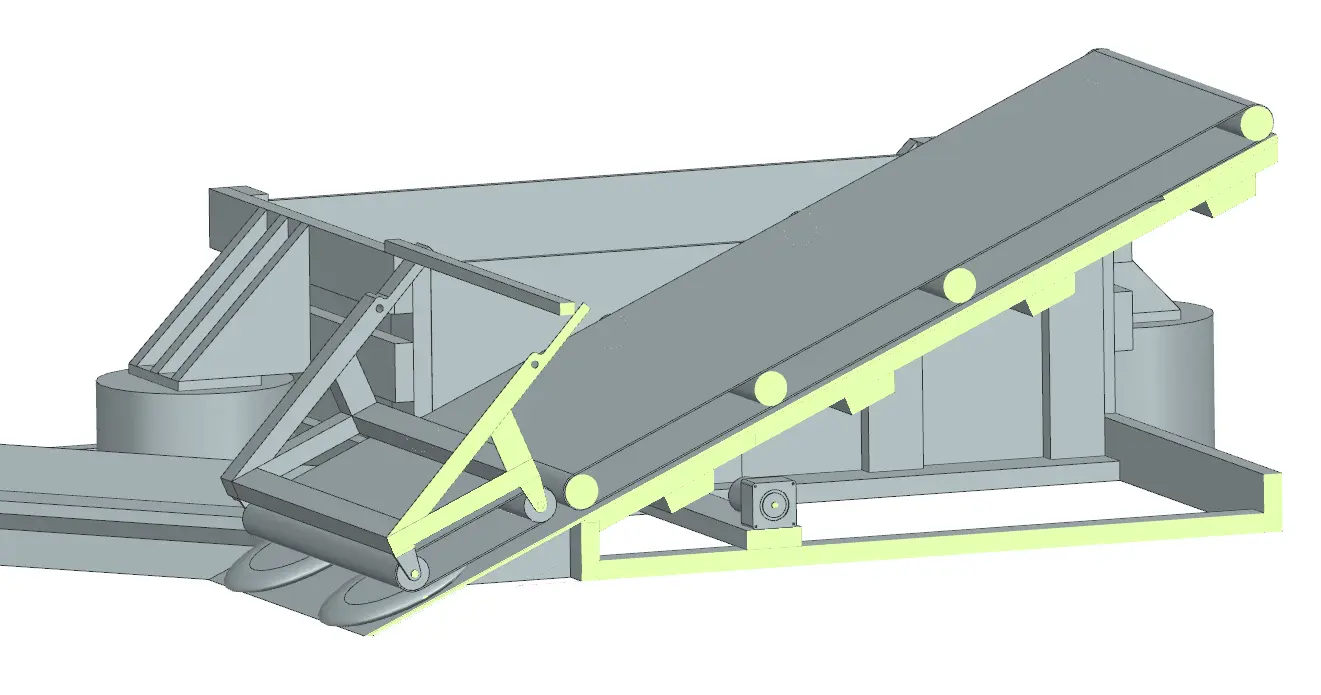

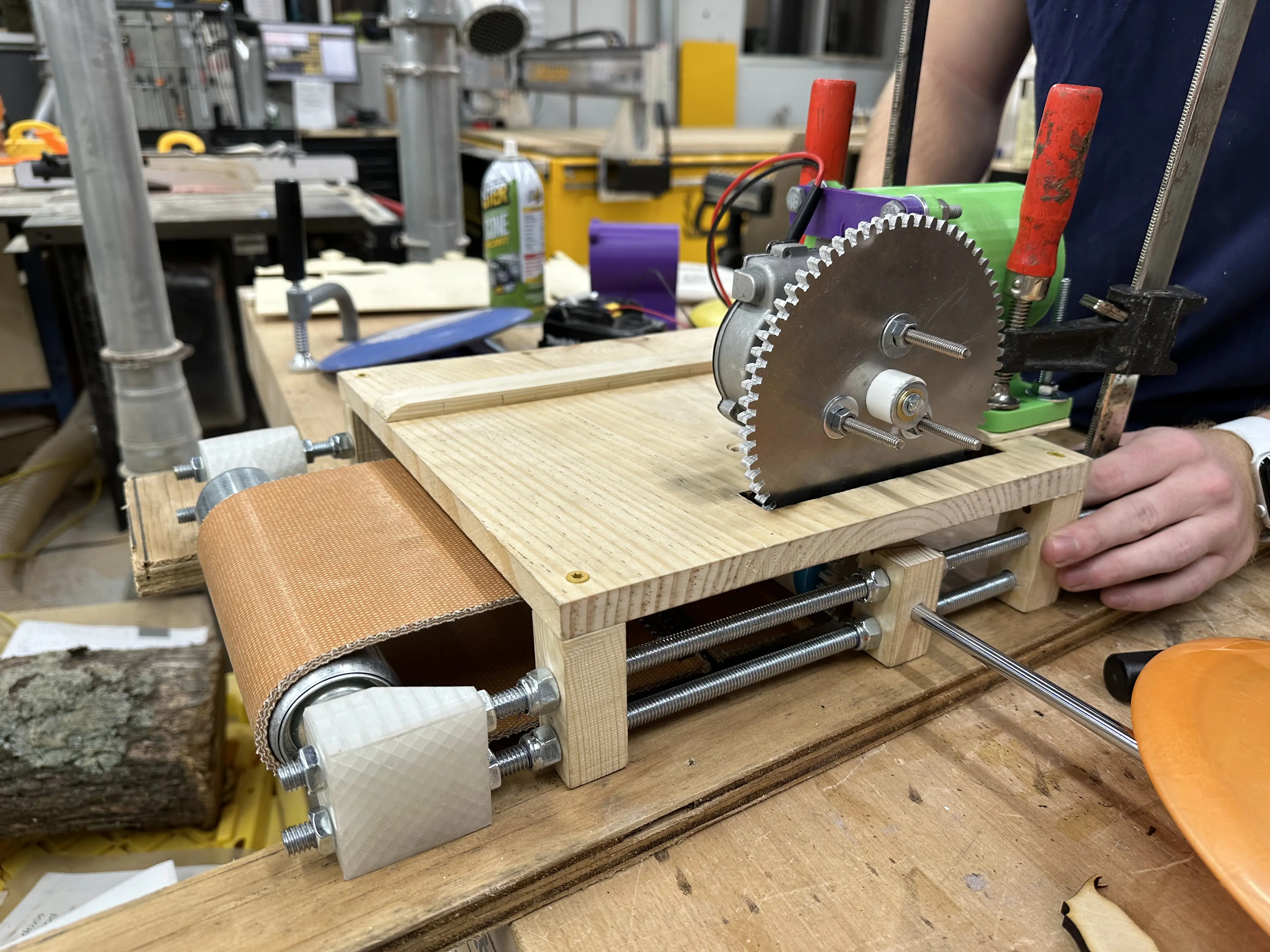

In the end (I do NOT know the process as I wasn’t part of it), we came up with this (from the non-scaled down design version):

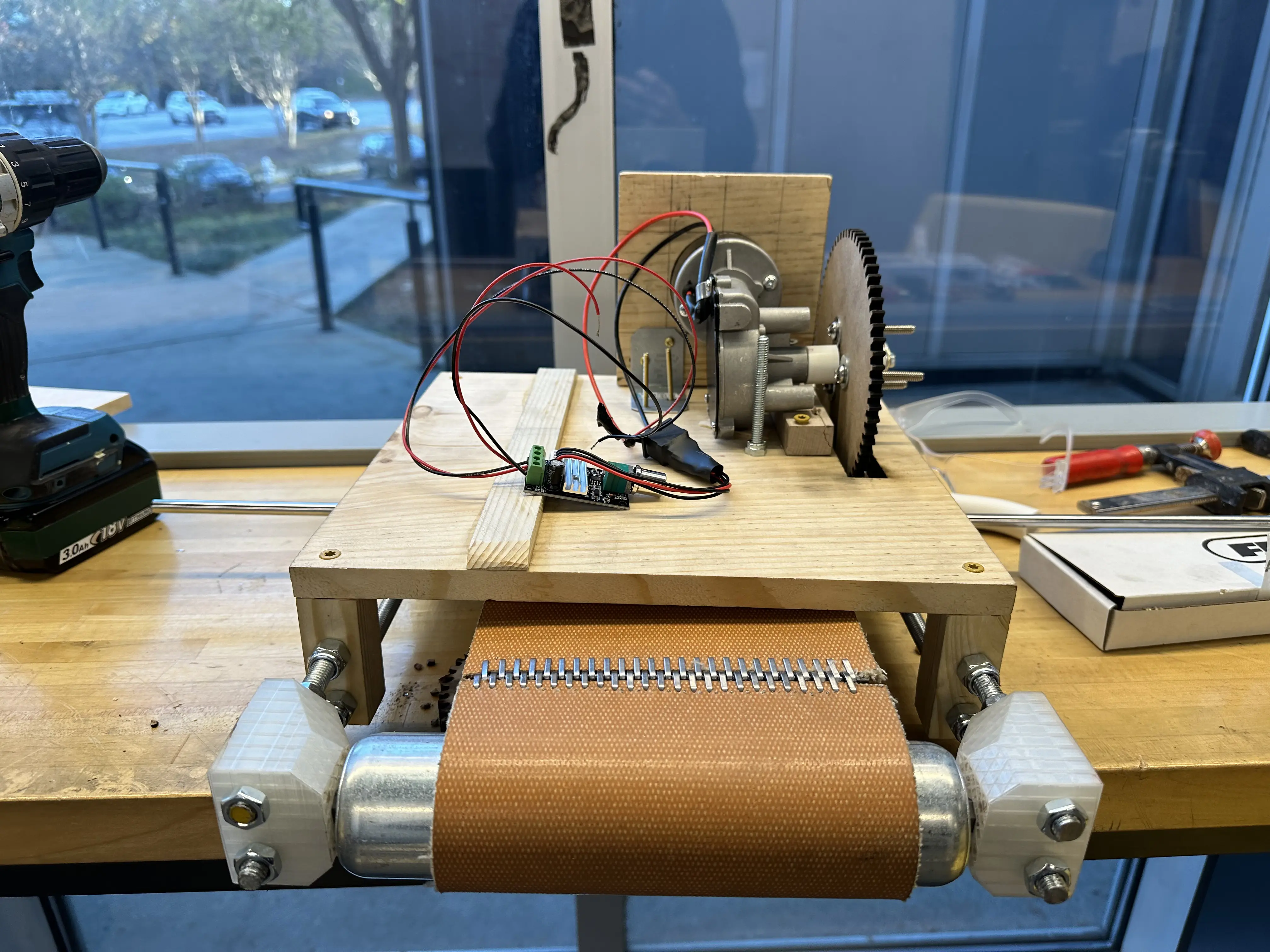

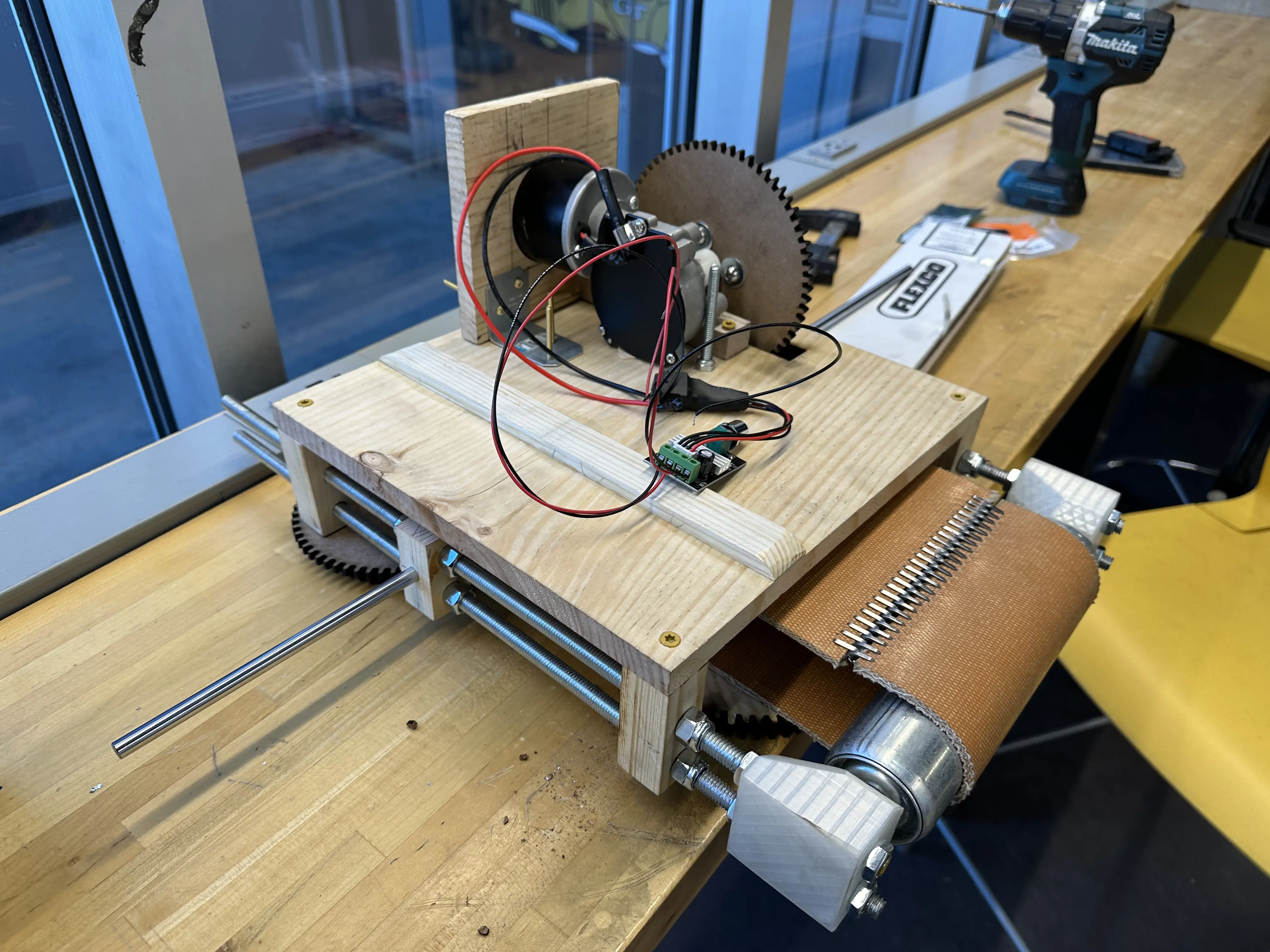

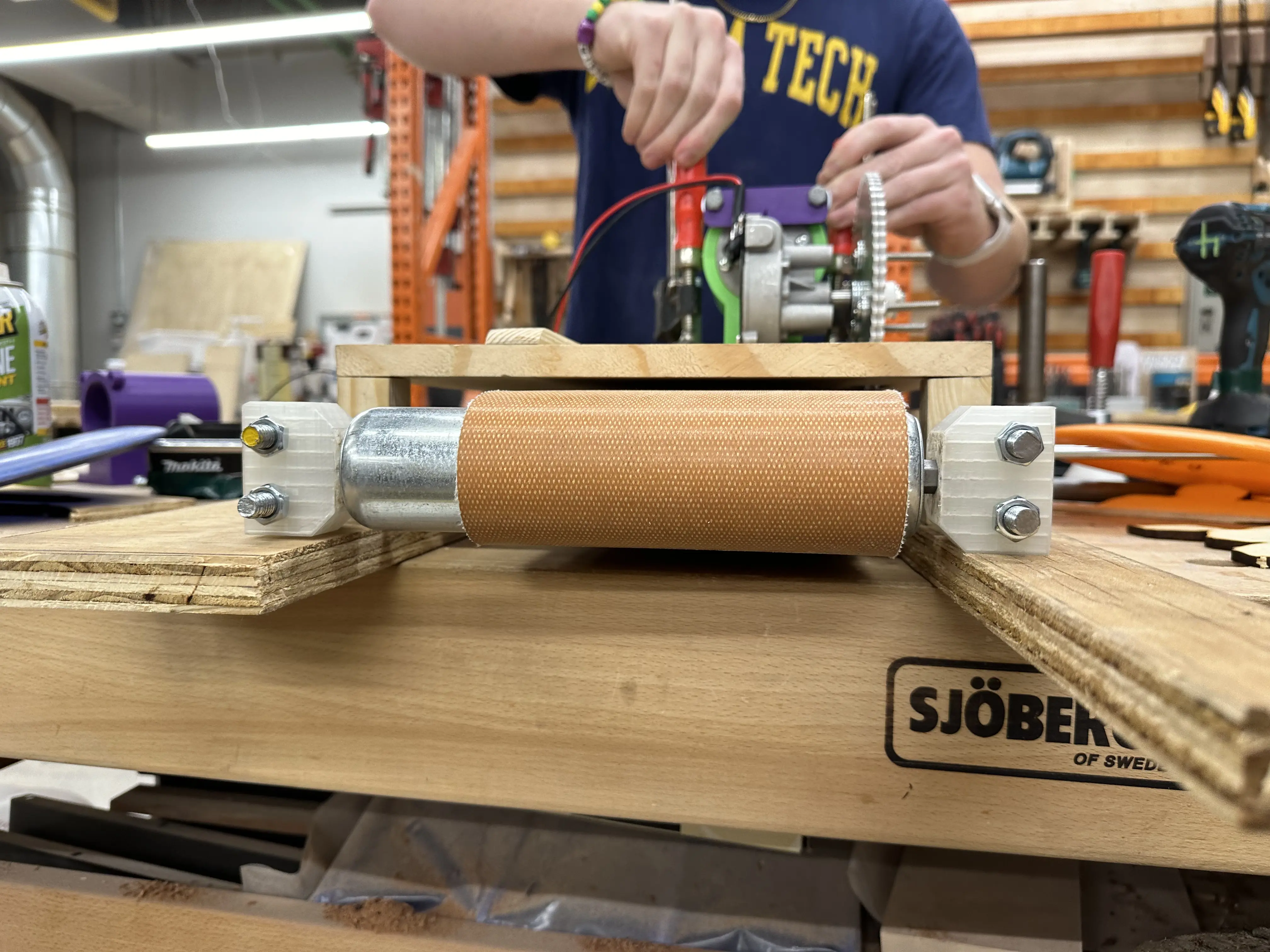

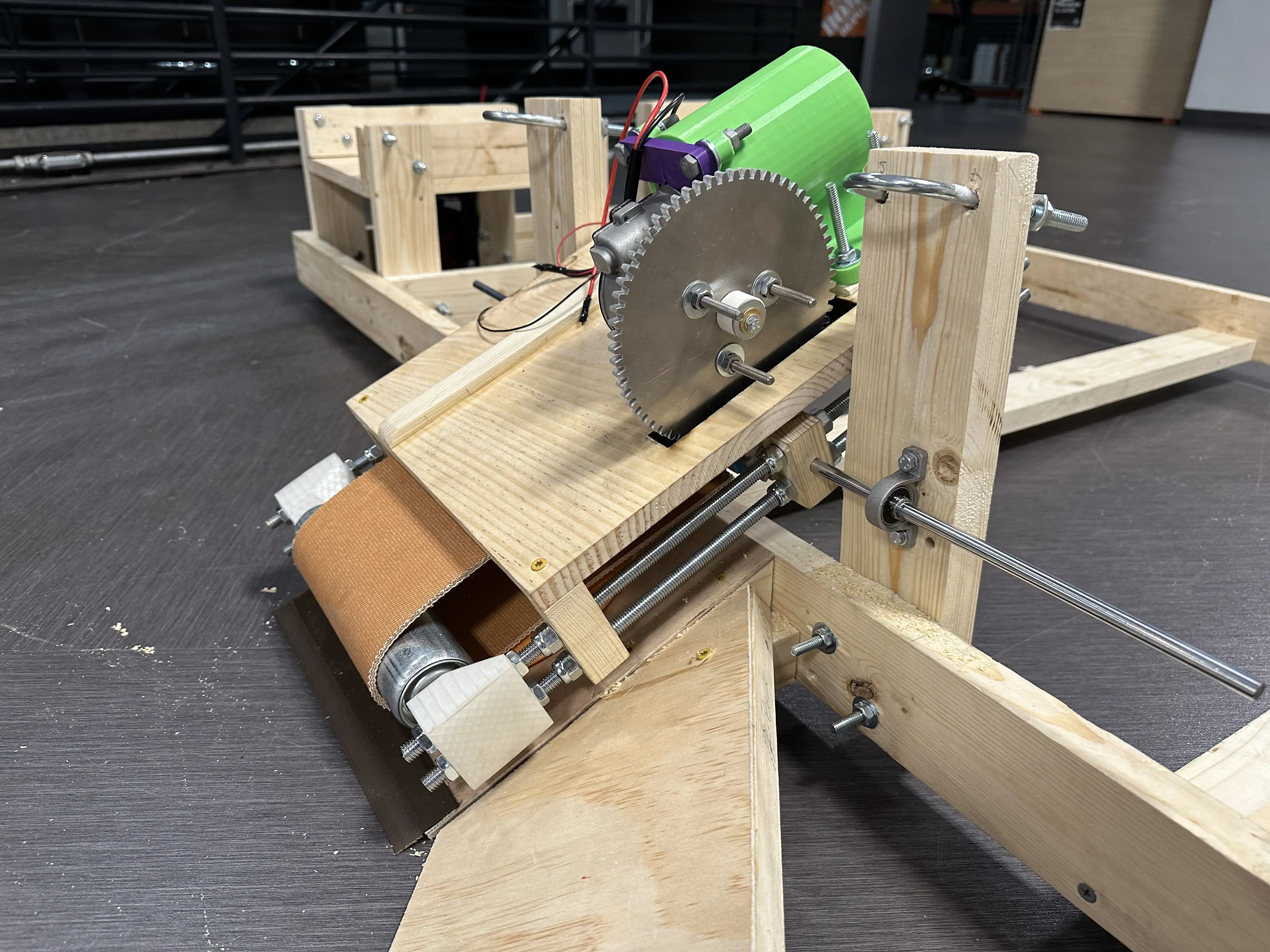

However, we built a scaled down version instead, which you can see here:

| — | — |

|---|---|

|  |

|  |

This was awful to assemble. I don’t know what they teach MEs. Also, Home Depot sold us the wrong nuts, so we had to use locknuts instead, which made assembly and belt tensioning an extremely tedious process.

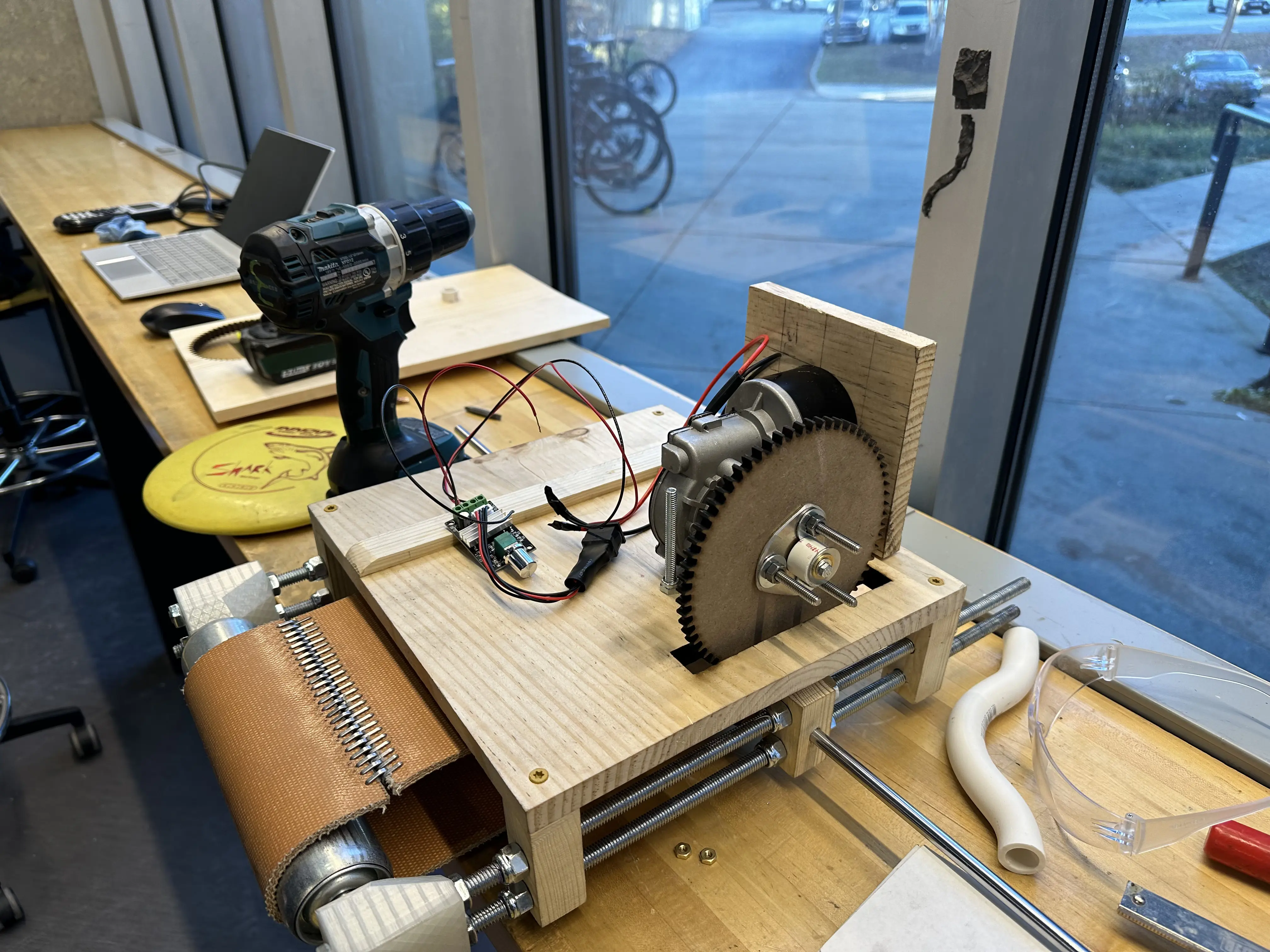

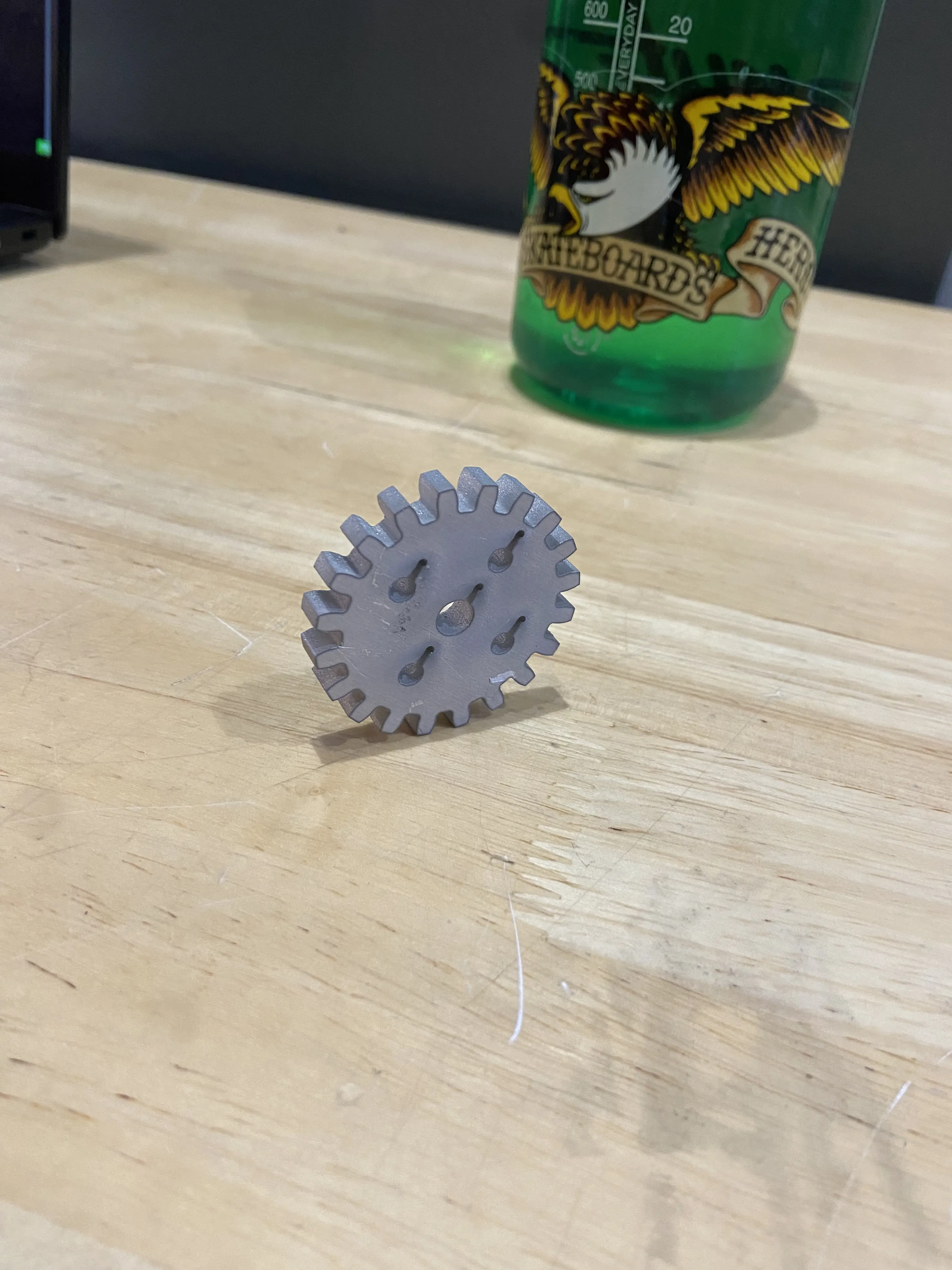

On a side note, yes the gear broke. It’s a bad quality wood that all MEs use in one of their important classes (ME 2110), so it was just habit to laser cut the gear and use that material. It broke due to the motor’s torque. The material was MDF.

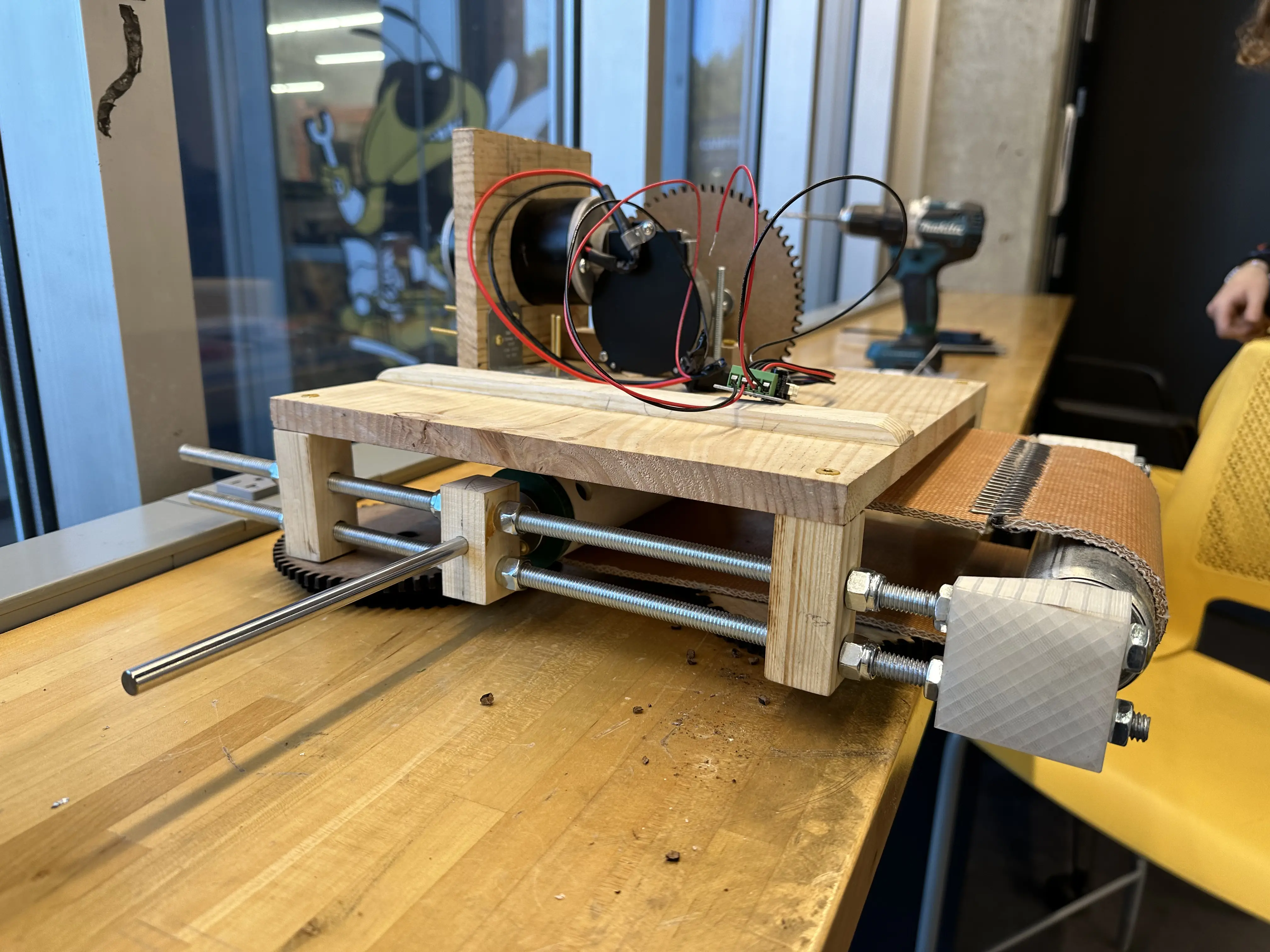

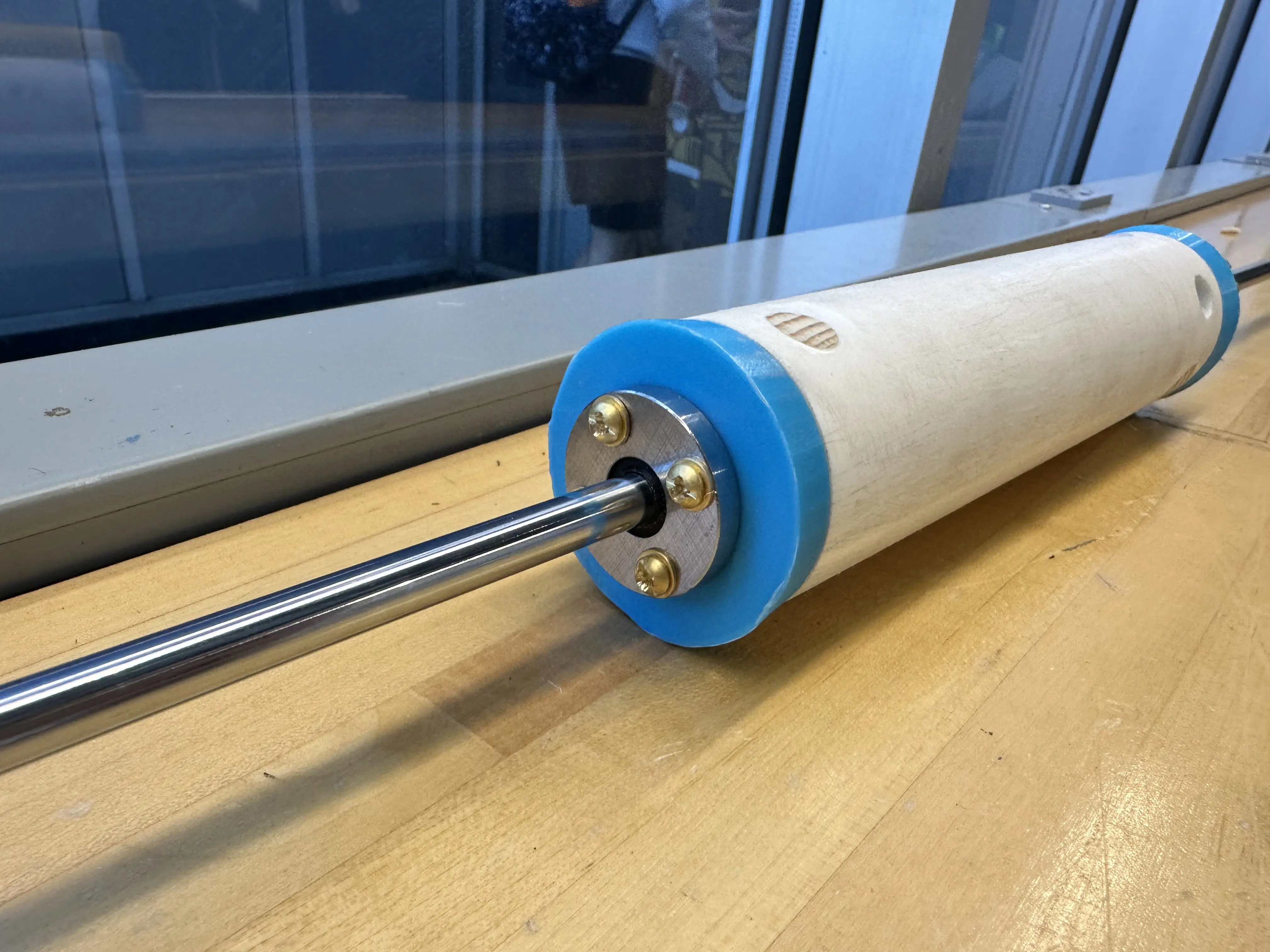

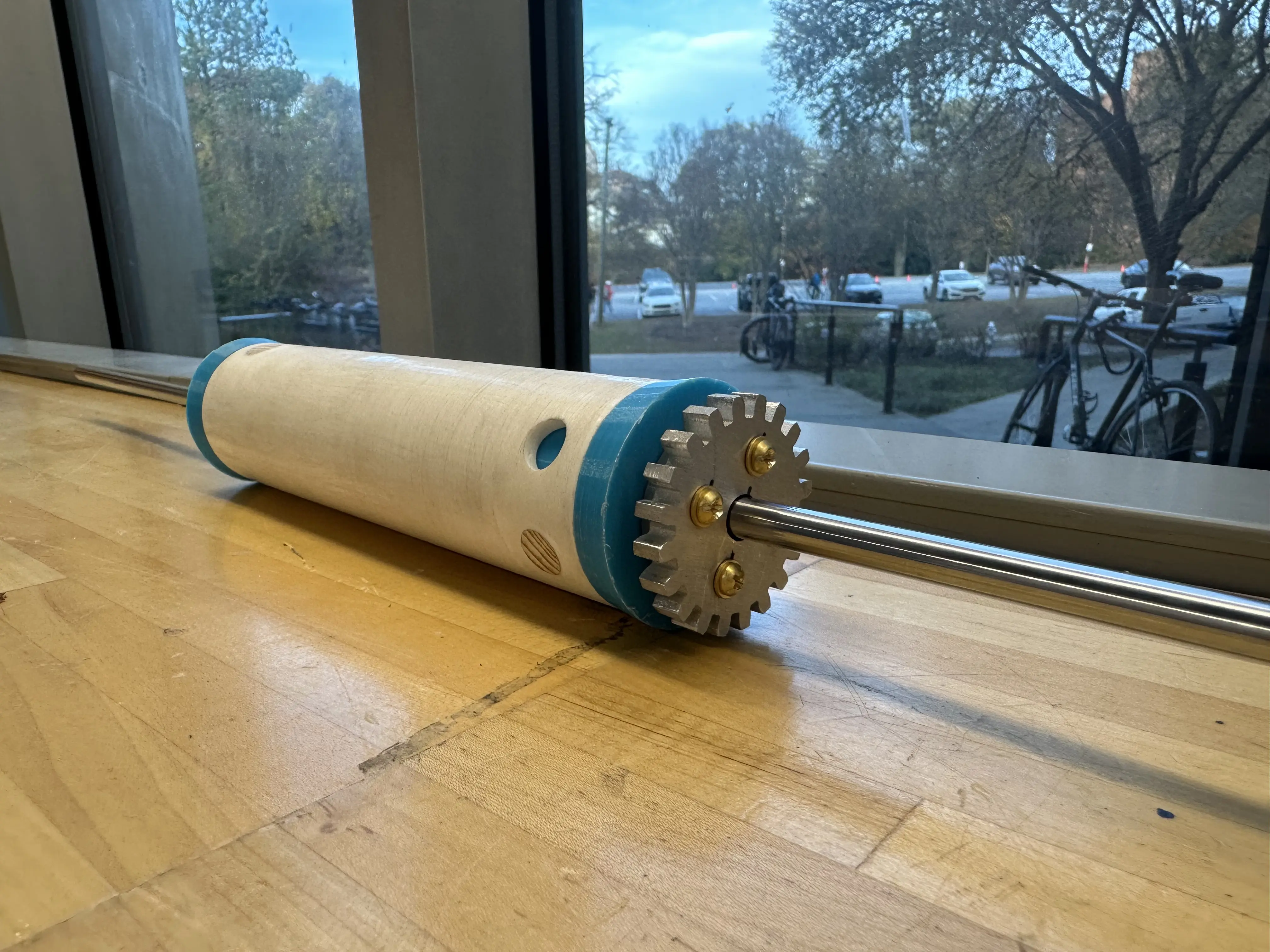

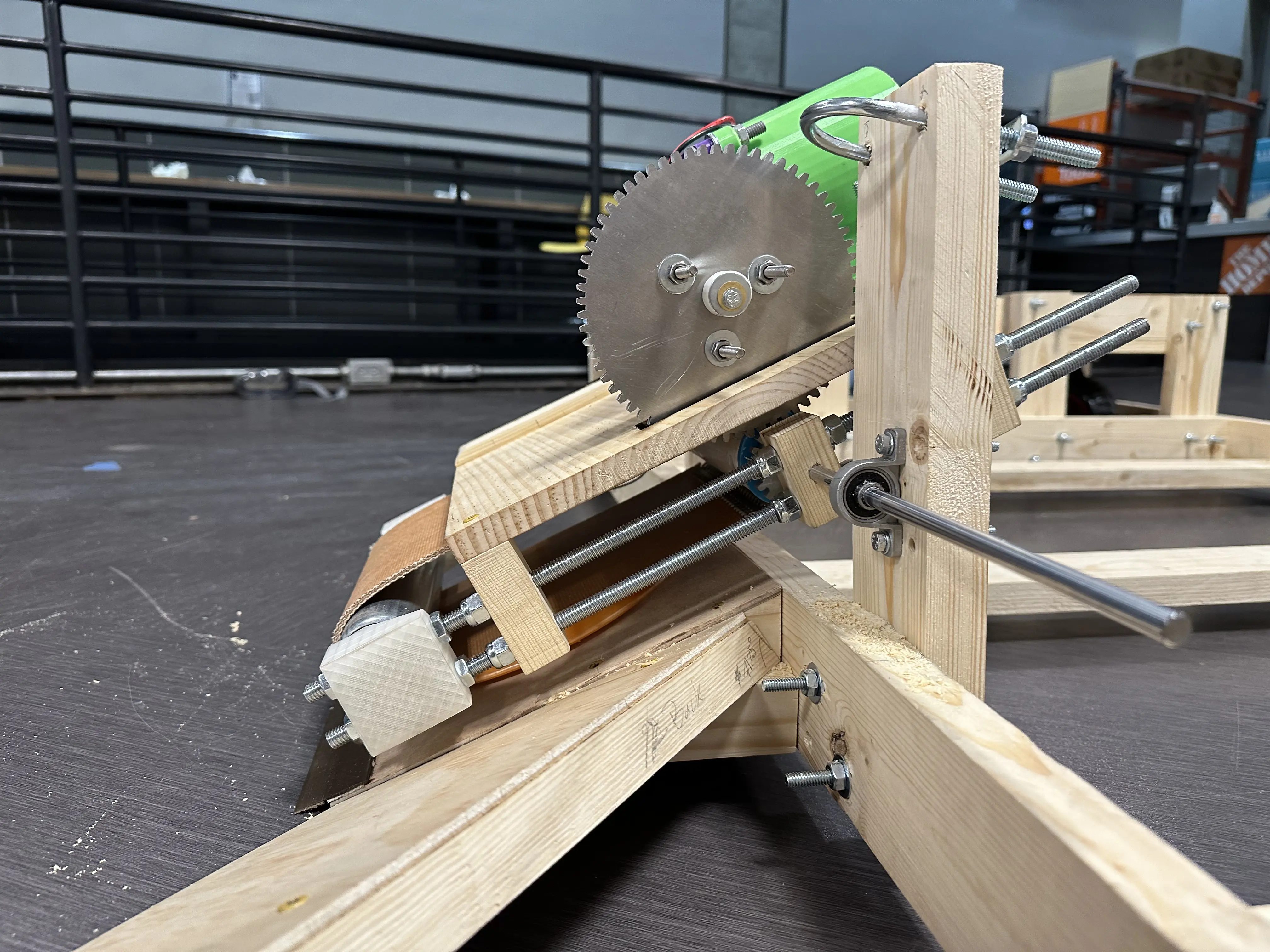

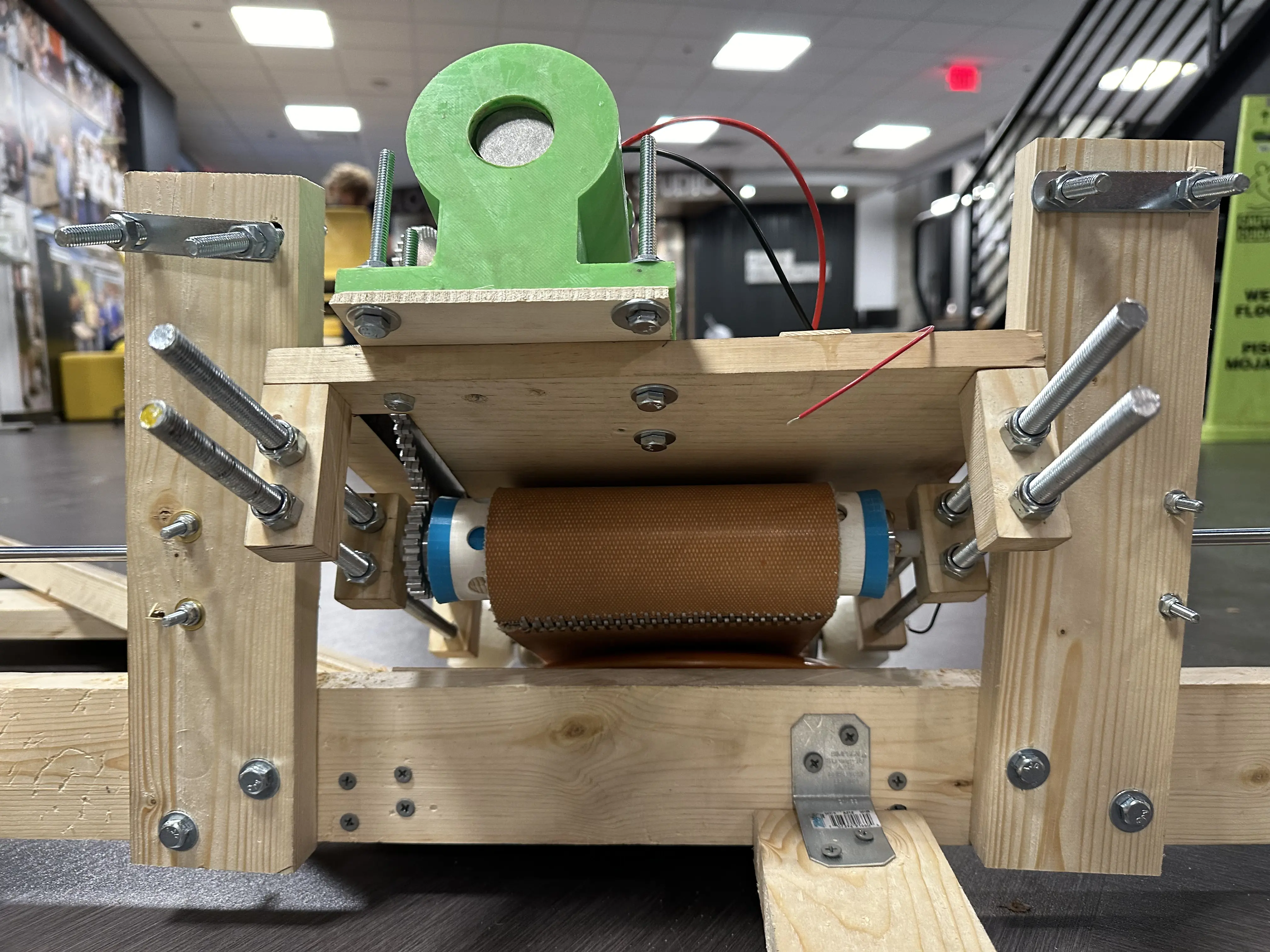

We therefore had to disassemble the conveyor system over 4 times, as we tried to fix it, until we water-jet 1/8th aluminum (that we then stacked together, to make 1/4th inch). There are 2 gears, here is the bottom roller with the gear.

| — | — |

|---|---|

|  |

|  |

You can see the motor we used here. It is a DC 12V (so we could plug it into a hypothetical UTV), 60W Reversible Gear Motor.

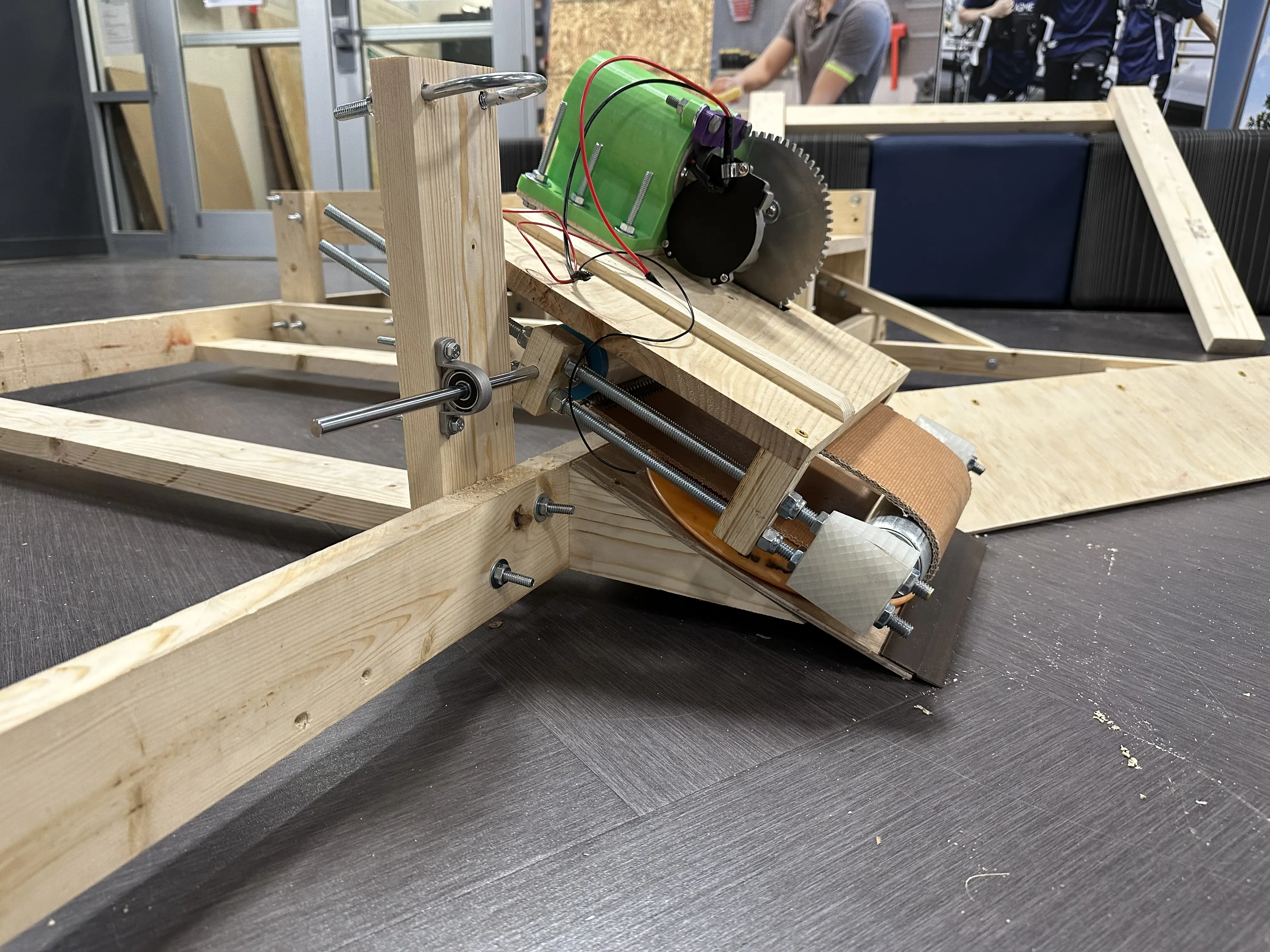

Here is what the subsystem looked like with the metal gears:

| — | — |

|---|---|

|  |

Final Assembly

After tensioning the belt, we tested out the motor and it worked! We were very proud and have it on video! However, I might have been a goofball, or our ECE depending how you look at it. In short, we used a power drill battery (18V) to power the motor, however we had a speed controller too. This motor speed controller needed to be plugged in correctly (since we had no ground), and either the 18V fried it or I wired it wrong. Anyway, the speed controller was fried before we would test our product on grass. The ECE said that he should have ordered 2, but I was sad regardless as this happened at 2am, the day before the final expo.

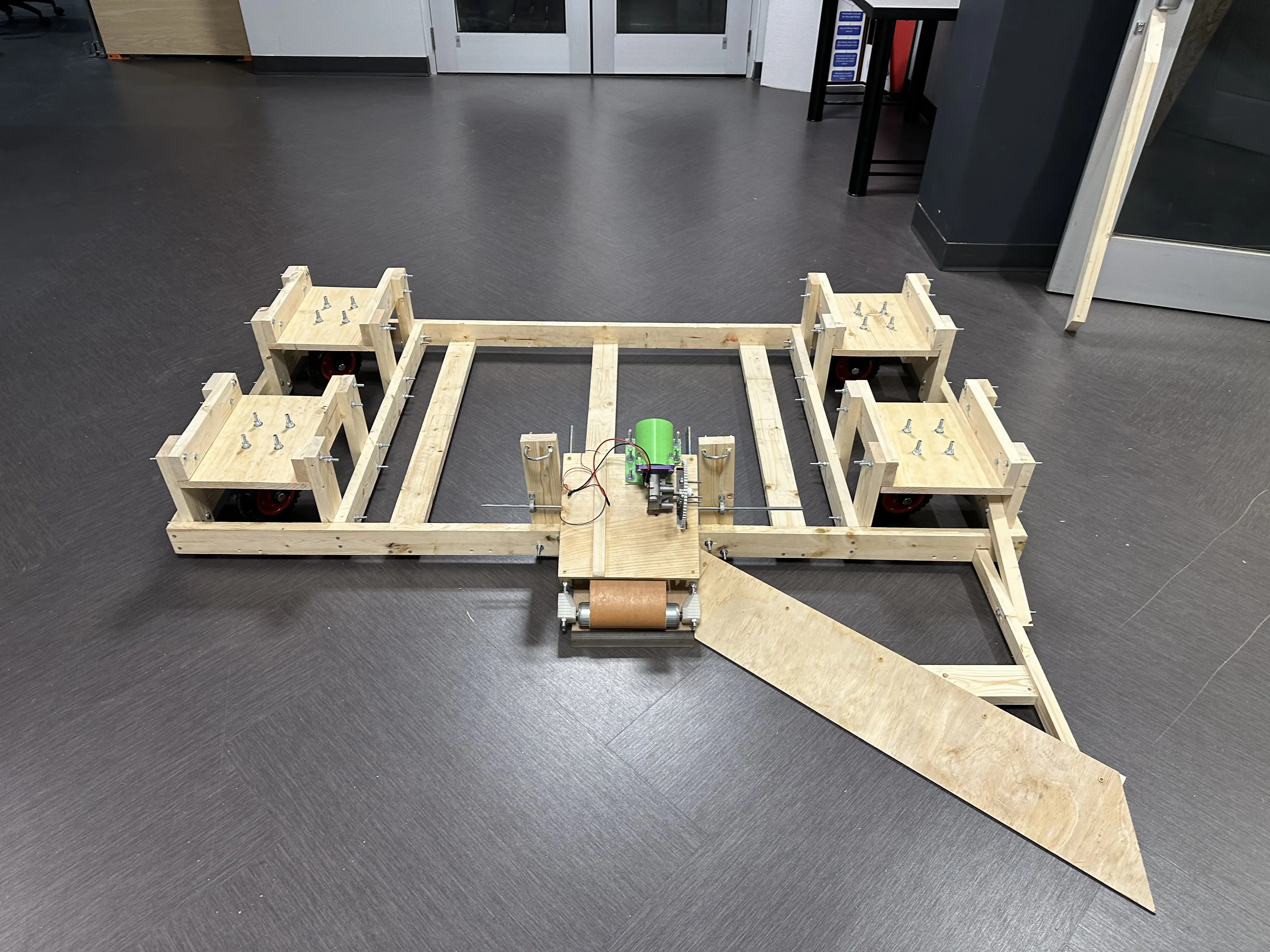

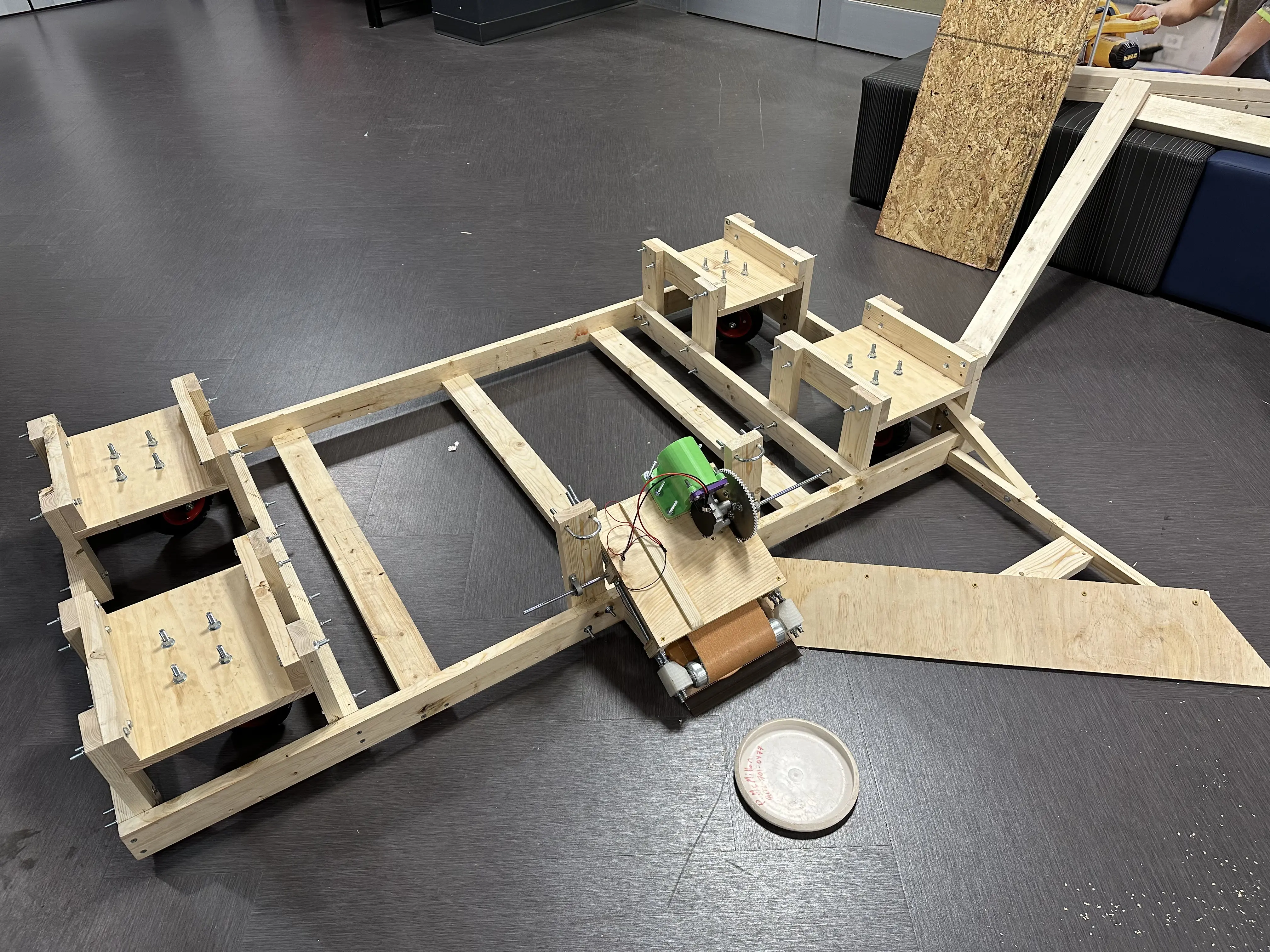

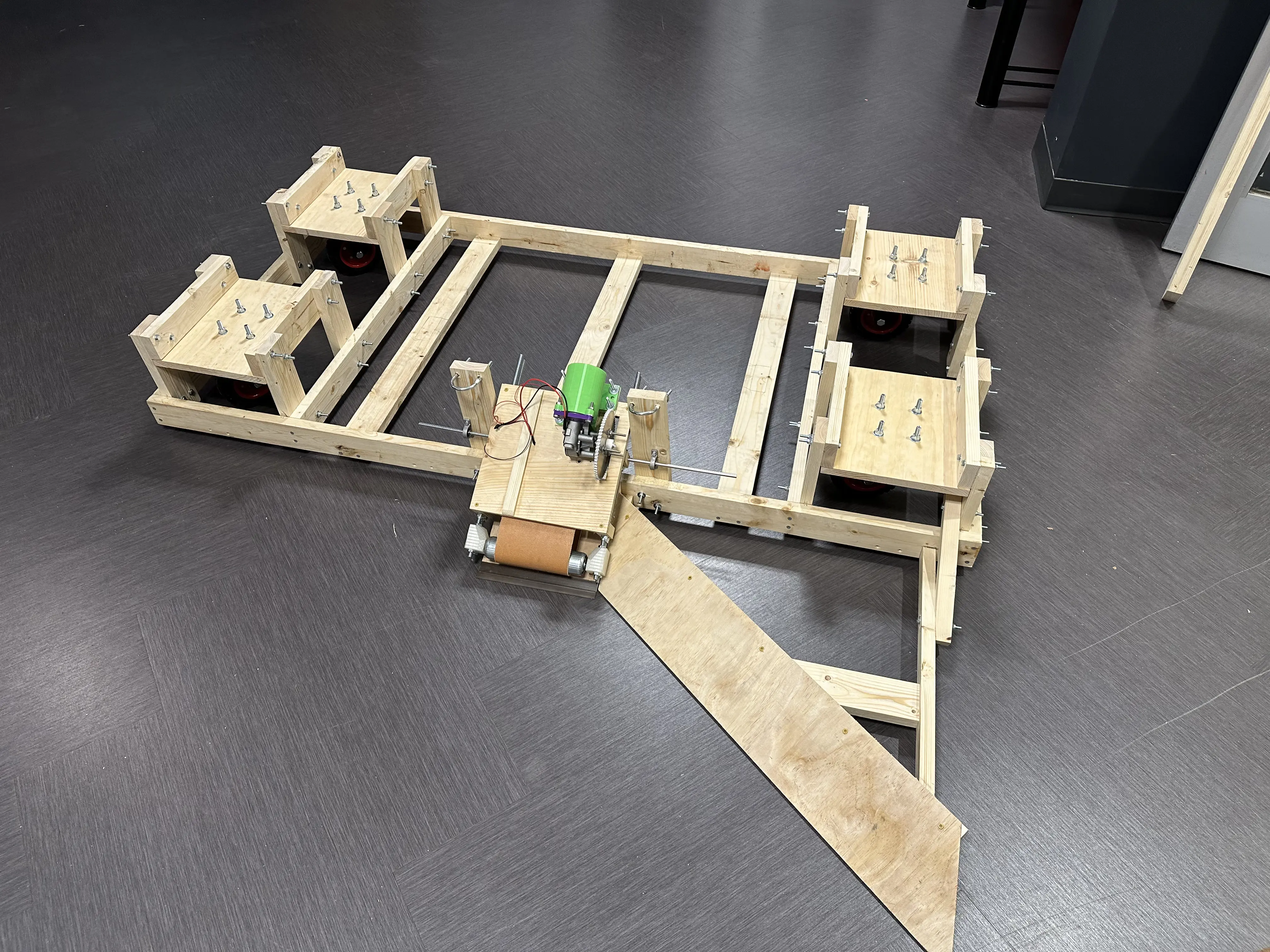

With no time to find a new one, we assembled our final product. Here it is!

| — | — |

|---|---|

|  |

|  |

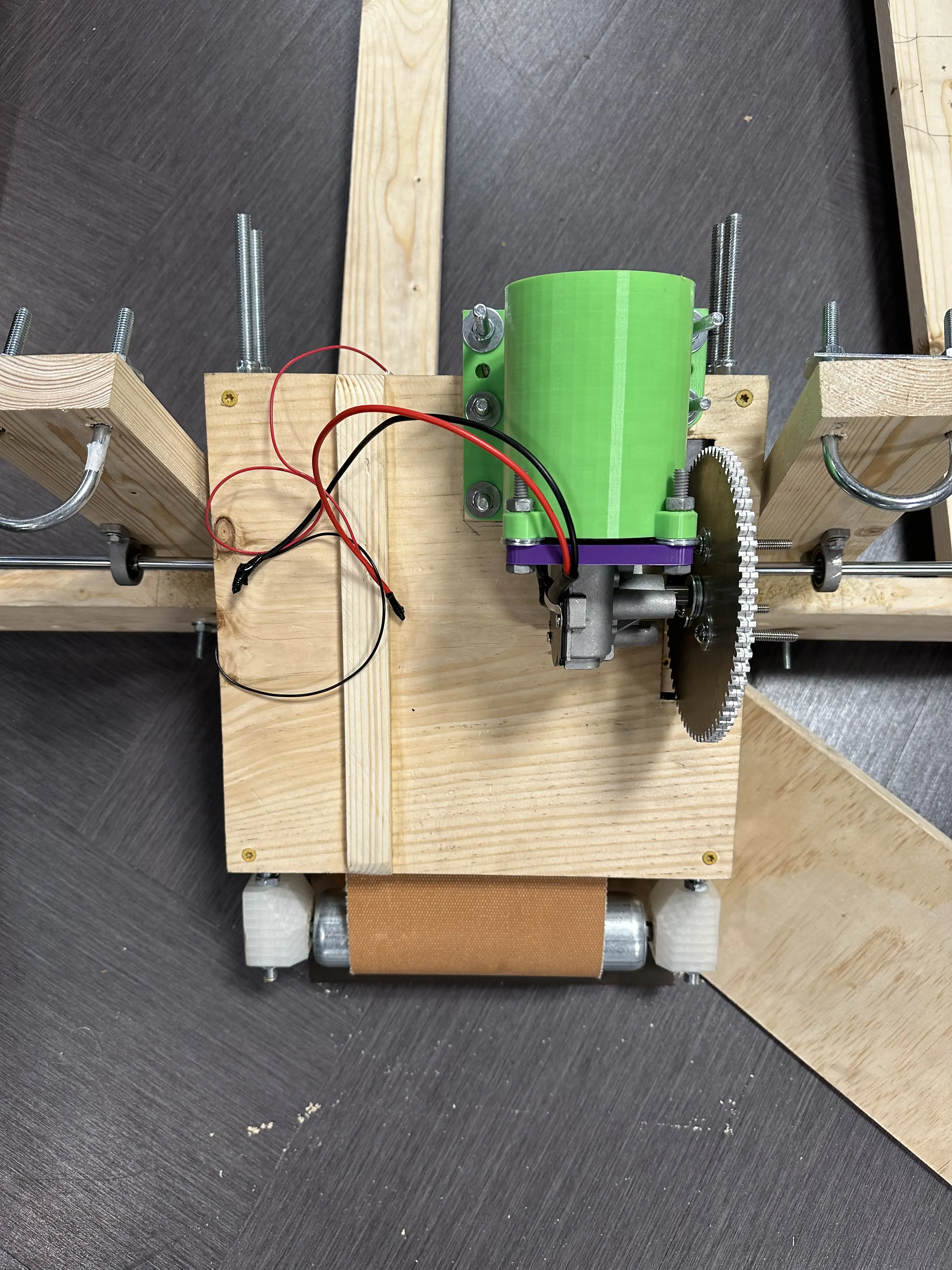

Here are close-ups of the conveyor mount.

| — | — |

|---|---|

|  |

|  |

Yes some of the wood is screwed in crooked but ECE guy and I drilled these holes very late into the night…

Final thoughts

I’m very glad I didn’t make a translation app. I joined this team because I really wished to get my hands dirty, and learn new skills. I learned woodworking, which I thoroughly enjoyed and would have never done without this project. My team was a fun bunch of guys, and I’m a tad sad that they are graduating. All in all, I had a good time!

By the way, the cost for all the materials was $800, without counting the machinery uses, the 3D printing filament, and everything else provided by Georgia Tech.

If you have any questions, or I made a spelling mistake, please DM me on twitter!.